Key Features and Benefits:

1. Durability: Steel ball valve lockouts are constructed from high-quality steel, ensuring their durability and resistance to harsh industrial environments. This robust construction guarantees that the lockout will withstand the rigors of daily use, providing long-lasting protection.

2. Versatility: These lockouts are designed to fit a wide range of valve sizes, making them suitable for various industrial applications. Their adjustable design allows for easy installation and removal, ensuring compatibility with different valve handles.

3. Visible and Recognizable: Steel ball valve lockouts are typically bright in color, making them highly visible and easily recognizable. This visual prominence serves as a visual reminder to workers that the valve is locked out and should not be operated. Additionally, the lockouts often feature clear labeling or warning signs, further enhancing their visibility and ensuring clear communication.

4. Compliance with Safety Standards: Steel ball valve lockouts are engineered to meet or exceed industry safety standards. By adhering to these standards, companies can ensure compliance with regulatory requirements and demonstrate their commitment to maintaining a safe working environment.

5. Ease of Use: These lockouts are designed to be user-friendly, allowing for quick and hassle-free installation. Their intuitive design ensures that workers can easily understand how to apply and remove the lockout, minimizing downtime and maximizing efficiency.

Implementing Steel Ball Valve Lockouts:

To effectively implement steel ball valve lockouts in an industrial setting, it is essential to establish comprehensive lockout/tagout procedures. These procedures should include clear instructions on how to identify, apply, and remove the lockouts. Additionally, training programs should be conducted to educate workers on the importance of lockout procedures and the proper use of steel ball valve lockouts.

Steel ball valve lockouts play a crucial role in ensuring the safety of workers in industrial environments. By immobilizing ball valves and preventing unauthorized operation, these lockouts significantly reduce the risk of accidents and hazardous releases. With their durability, versatility, visibility, and compliance with safety standards, steel ball valve lockouts are an indispensable tool for maintaining a safe working environment. Implementing these lockouts, along with comprehensive lockout/tagout procedures, demonstrates a commitment to worker safety and fosters a culture of safety in the workplace.

PRODUCT DETAILS:

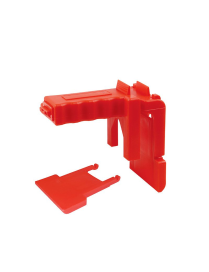

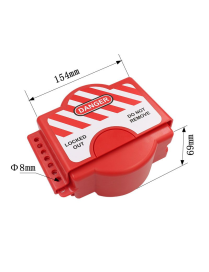

Made from hardened steel, surface treatment by high temperature spraying, rust proof. The single-piece design locks can quarter-turn ball valves in off position. Used on ball valve sizes from 6.35mm (1/4”) to 25mm (1”), hole diameter is 3/8”.

Material: Steel

Description: Standard Ball Valve Lockout

Brand Name: Prolockey

Service Temperature Range °F: -40℃-280℃

Lock Holes: 9.8mm

Color: Red

Total Length: 110mm

Body Width: 155mm

Body Height: 15mm

Product Net Weight: 0.342kg

INSTALLATION STEPS:

Security policy

Security policy

Delivery policy

Delivery policy

Return policy

Return policy