- New

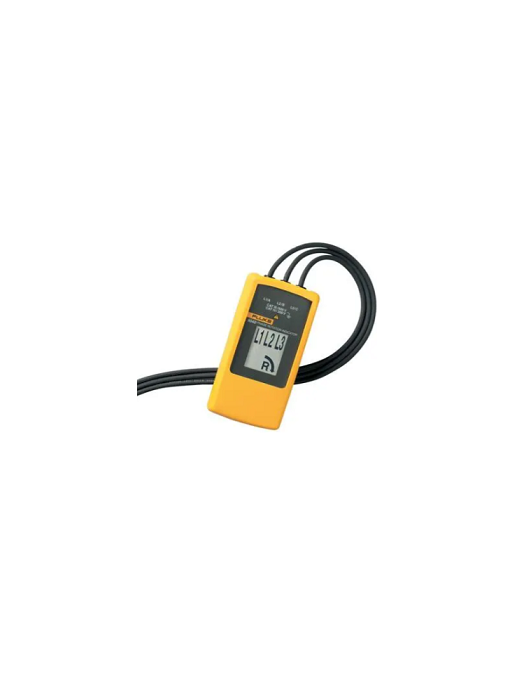

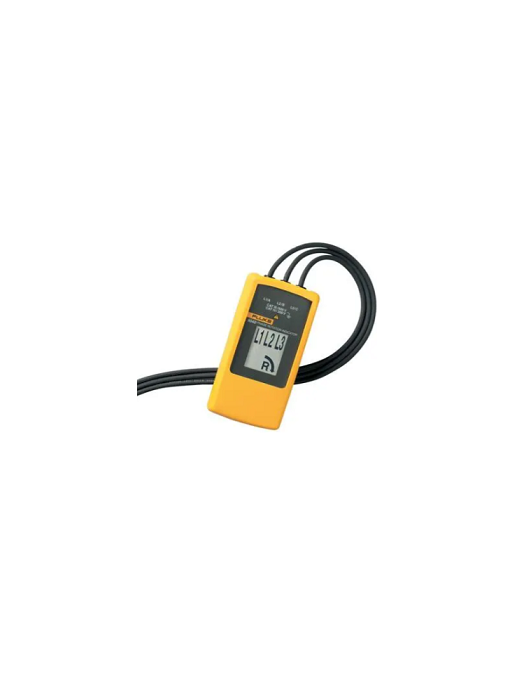

The Fluke 9040 is effective for measuring phase rotation in all areas where three phase supplies are used to feed motors, drives and electrical systems. The Fluke 9040 is a rotary field indicator and can provide clear indication of the 3 phase via an LCD display and the phase rotation direction to determine correct connections. It allows rapid determination of phase sequence and has a voltage (up to 700 V) and frequency range suitable for commercial and industrial applications. The included test probes have a variable clamping range for safe contact, also in industrial sockets.

Security policy

Security policy

(edit with the Customer Reassurance module)

Delivery policy

Delivery policy

(edit with the Customer Reassurance module)

Return policy

Return policy

(edit with the Customer Reassurance module)