Key Considerations for Plug Valve Lockout:

1. Identify and Assess Risks: Before implementing plug valve lockout procedures, it is crucial to conduct a thorough risk assessment. Identify potential hazards associated with the specific plug valve, such as the release of toxic substances, high pressure, or extreme temperatures. Assess the potential consequences of a valve failure or accidental operation, and determine the appropriate lockout measures accordingly.

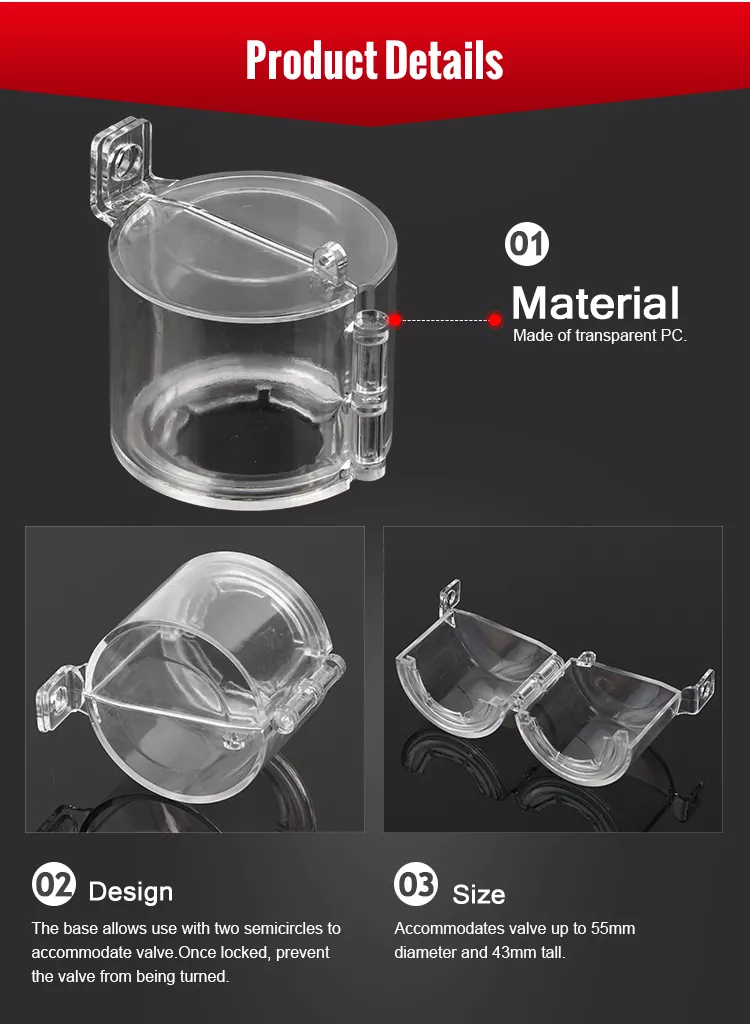

2. Select the Right Lockout Devices: There are various lockout devices available in the market specifically designed for plug valves. These devices typically include valve lockout covers, lockout hasps, and padlocks. Choose lockout devices that are compatible with the size and type of plug valve in use. Ensure that the devices are durable, tamper-proof, and capable of effectively immobilizing the valve handle or lever.

3. Develop Clear Lockout Procedures: Establish comprehensive lockout procedures that clearly outline the steps to be followed when implementing plug valve lockout. Include detailed instructions on how to properly install and remove lockout devices, as well as any additional precautions or safety measures. Train all relevant personnel on these procedures to ensure consistent and effective implementation.

4. Communicate and Label: Clearly communicate the presence of lockout devices and the reason for their installation. Use standardized lockout tags or labels to indicate that a plug valve is locked out for maintenance or repair. These visual cues serve as a warning to others and help prevent accidental operation of the valve.

5. Regular Inspection and Maintenance: Regularly inspect and maintain lockout devices to ensure their proper functioning. Over time, lockout devices may become damaged or worn out, compromising their effectiveness. Replace any defective devices promptly to maintain a high level of safety.

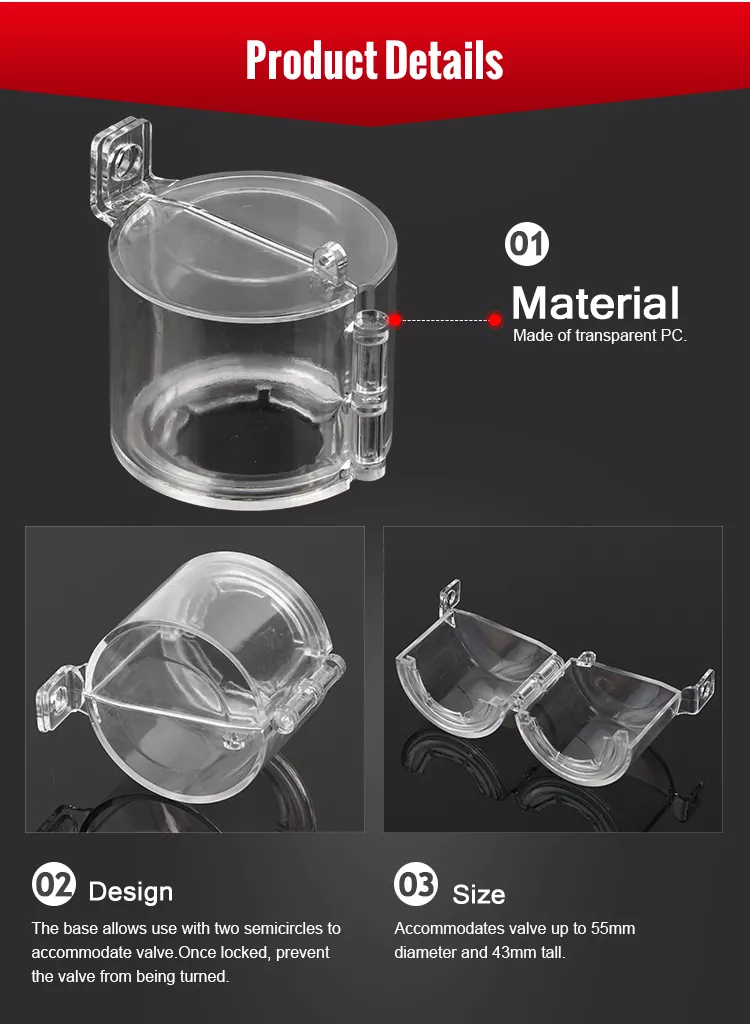

PRODUCT DETAILS:

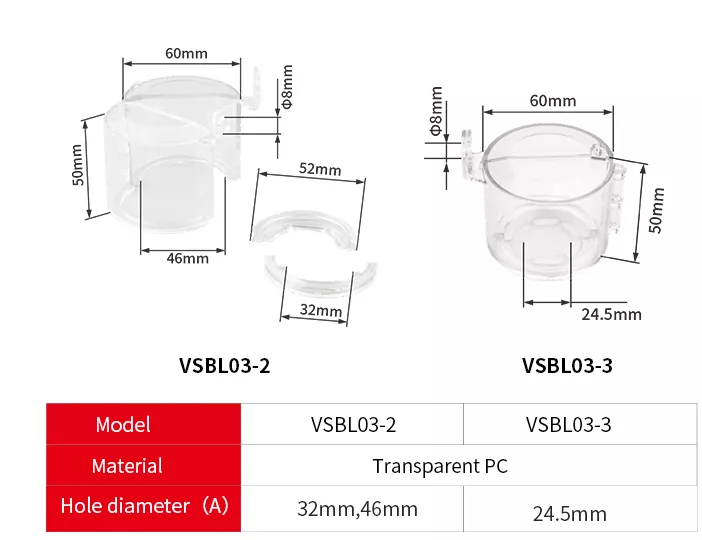

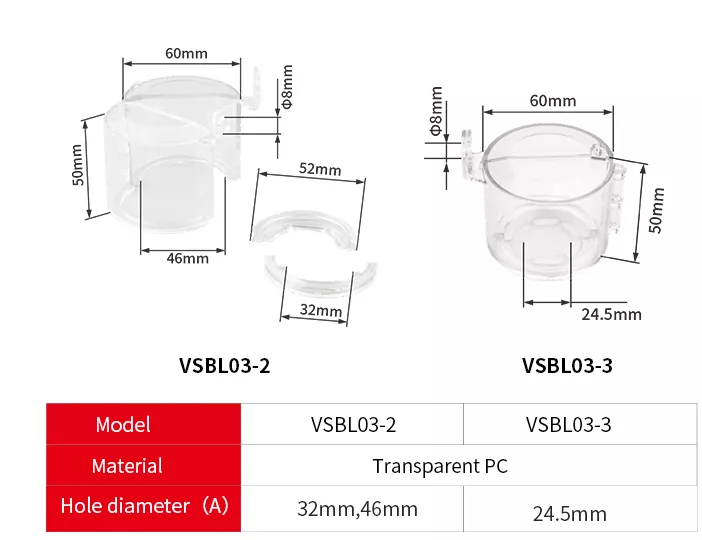

Made of transparent PC, withstand temperature from -20℃ to +120℃. Once locked, prevent the valve from being turned. The base allows use with two semicircles to accommodate valve. Accommodates valve up to 55mm diameter and 43mm tall. Fits 32mm-46mm diameter valve.

Product Number: VSBL03-3

Material: PC2805

Description: Diaphragm Valve Lockout

Brand Name: Prolockey

Service Temperature Range °F: -20℃-120℃

Lock Holes: 8mm

Color: Transparency

Total diameter: 60mm

Inner diameter: 54.7mm

Body Height: 49mm

Locking diameter: 24.4mm

Product Net Weight: 0.042kg

Conclusion:

Plug valve lockout is a critical safety measure that ensures the safe isolation of plug valves during maintenance or repair work. By implementing effective lockout procedures and using appropriate lockout devices, companies can protect workers from potential hazards and comply with safety regulations. Prioritizing safety in industrial environments not only safeguards employees but also enhances productivity and reputation. Remember, when it comes to plug valve lockout, prevention is key.

Security policy

Security policy

Delivery policy

Delivery policy

Return policy

Return policy