Benefits of Gate Valve Lockouts:

1. Enhanced Safety: The primary purpose of gate valve lockouts is to create a safe working environment. By effectively immobilizing gate valves, these lockouts prevent unauthorized or accidental operation, reducing the risk of accidents, injuries, and potential fatalities. Workers can perform their tasks with confidence, knowing that the energy source is securely isolated.

2. Compliance with Regulations: Many regulatory bodies and industry standards mandate the use of gate valve lockouts during maintenance or repair activities. By implementing these lockouts, employers ensure compliance with legal requirements, avoiding penalties and legal complications. Additionally, adhering to safety regulations demonstrates a commitment to employee well-being and fosters a positive work culture.

3. Increased Efficiency: Gate valve lockouts streamline maintenance procedures, allowing workers to complete tasks more efficiently. By immobilizing the valve, lockouts eliminate the need for constant monitoring, reducing downtime and increasing productivity. This efficient approach to maintenance ensures that equipment is serviced promptly, minimizing disruptions to operations.

Choosing the Right Gate Valve Lockout:

When selecting a gate valve lockout, several factors should be considered:

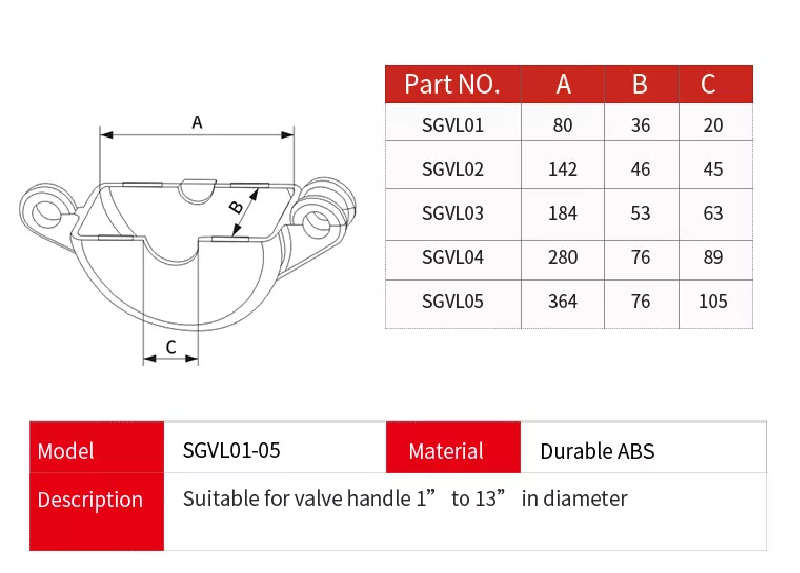

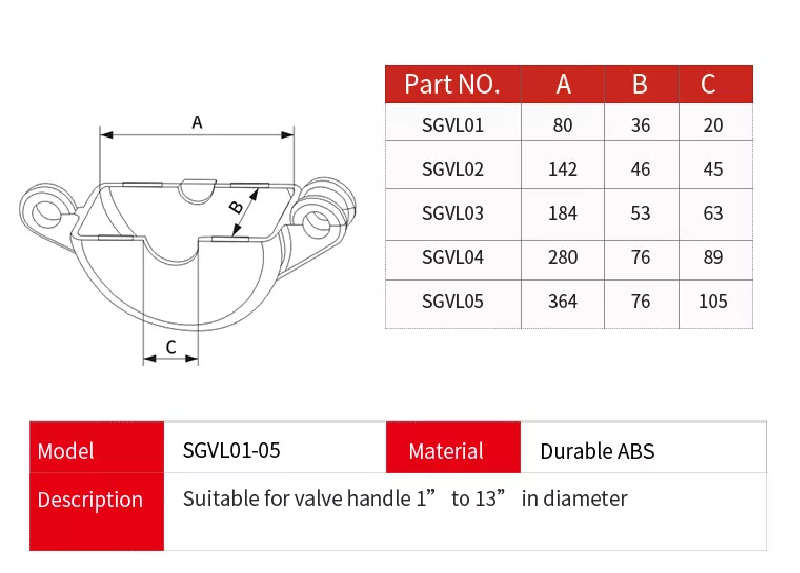

1. Compatibility: Ensure that the lockout device is compatible with the specific gate valve model and size in your facility. It should securely fit and effectively immobilize the valve, leaving no room for accidental operation.

2. Durability: Opt for lockouts made from high-quality materials that can withstand harsh industrial environments. Durable lockouts provide long-lasting protection and require minimal maintenance.

3. Ease of Use: Look for lockouts that are easy to install and remove. User-friendly designs facilitate efficient maintenance procedures, saving time and effort.

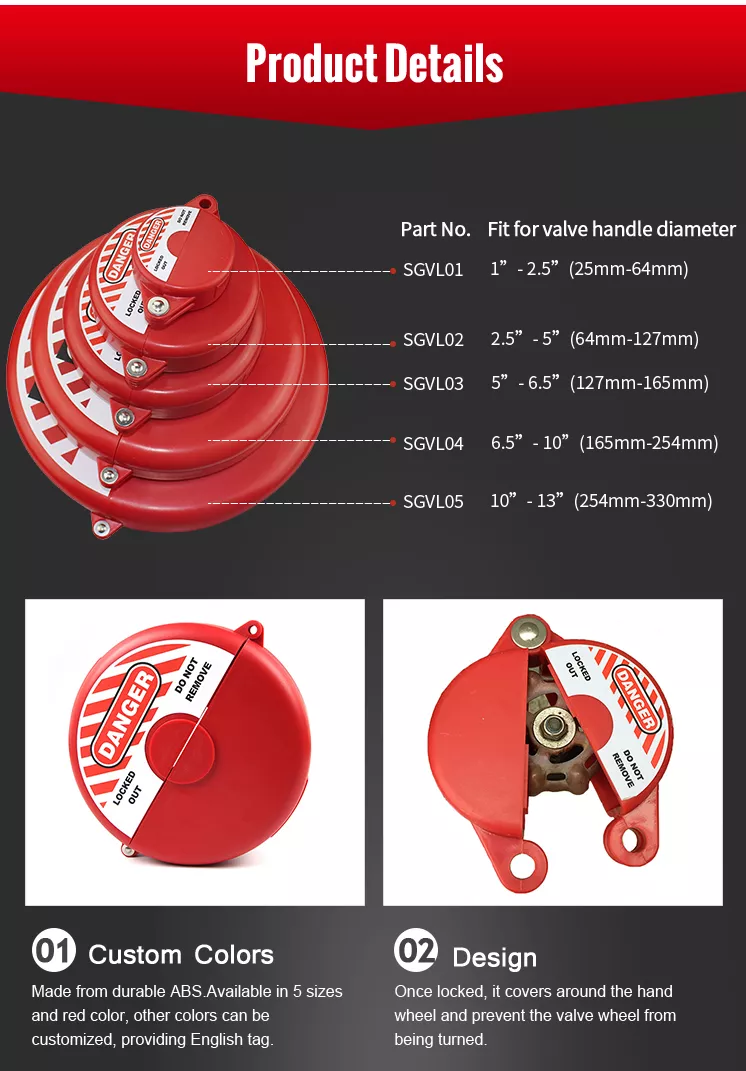

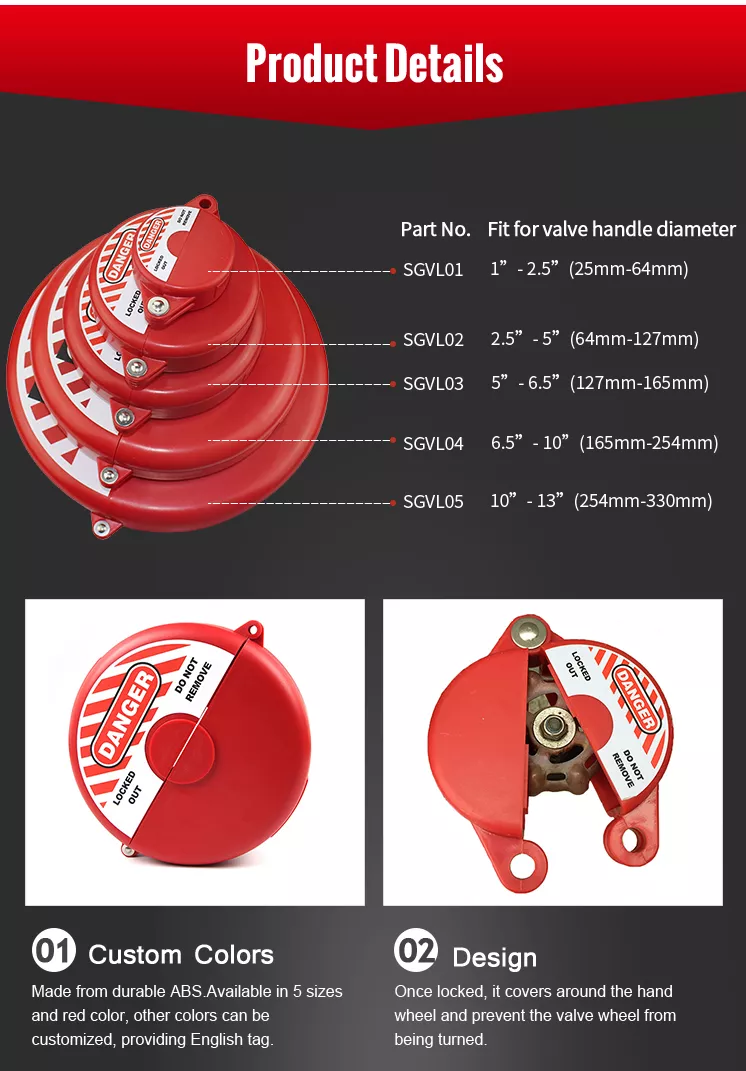

4. Visibility: Choose lockouts with bright colors and clear labeling to enhance visibility. This helps workers quickly identify the locked-out valve, reducing the risk of accidental operation.

PRODUCT DETAILS:

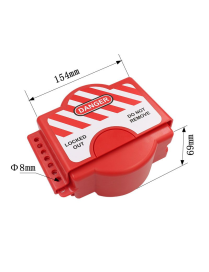

Made from durable ABS, withstand temperature from -20℃ to +90℃. Once locked, it covers around the hand wheel and prevent the valve wheel from being turned. Accept up to 1 padlock, locking shackle max diameter 9.5mm. Available in 5 sizes and red color, other colors can be customized, providing English tag. Transparent one can be customized.

Brand Name: Prolockey

Body Material: ABS750

Rivet Material: Stainless steel

Service Temperature Range °F: -20℃-90℃

Color: Red

Lock Holes: 9.8mm

APPLICATION:

INSTALLATION STEPS:

Conclusion:

In conclusion, gate valve lockouts play a crucial role in ensuring workplace safety and efficiency. By immobilizing gate valves, these lockouts prevent unauthorized or accidental operation, protecting workers from potential hazards. Compliance with regulations, increased efficiency, and careful selection of lockout devices are essential elements in creating a safe and productive work environment. Employers must prioritize the implementation of gate valve lockouts to safeguard their employees and uphold their commitment to workplace safety.

Security policy

Security policy

Delivery policy

Delivery policy

Return policy

Return policy