The Importance of Butterfly Valve Lockout:

While butterfly valves offer numerous benefits, they can pose a significant safety risk if not properly locked out during maintenance or repair activities. Accidental valve operation can result in severe injuries, equipment damage, or even environmental hazards. To mitigate these risks, a robust butterfly valve lockout system is essential.

Key Features of Butterfly Valve Lockout:

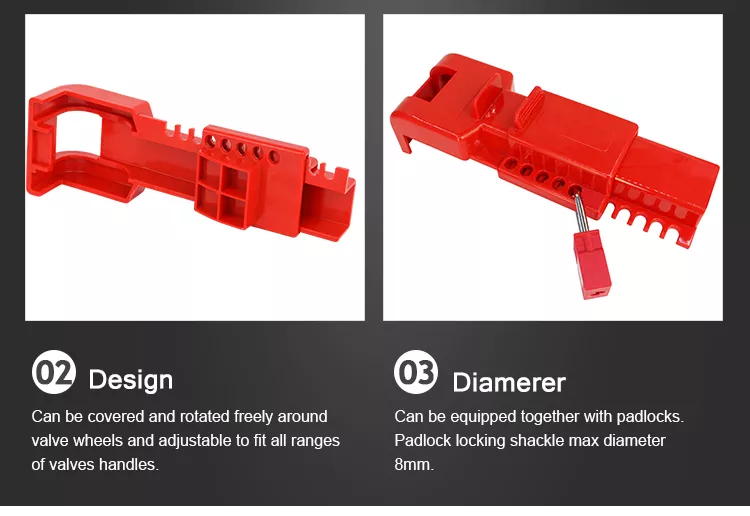

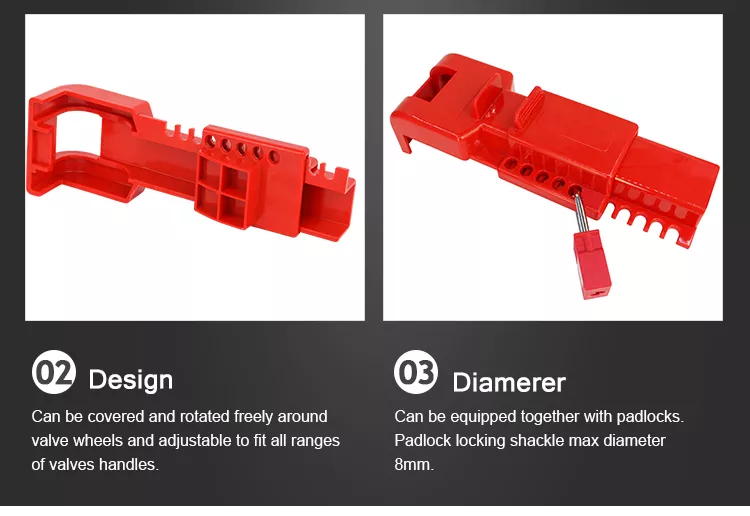

1. Versatility: Butterfly valve lockout devices are designed to fit a wide range of valve sizes and types, ensuring compatibility with various industrial applications. They offer flexibility and ease of use, allowing for efficient lockout procedures.

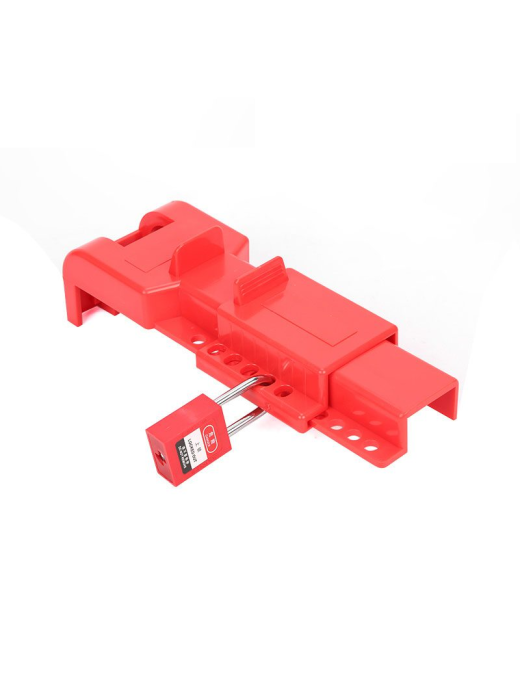

2. Secure Locking Mechanism: Butterfly valve lockout devices employ a secure locking mechanism that prevents unauthorized access or accidental valve operation. These devices typically feature multiple lockout points, ensuring complete isolation of the valve from energy sources.

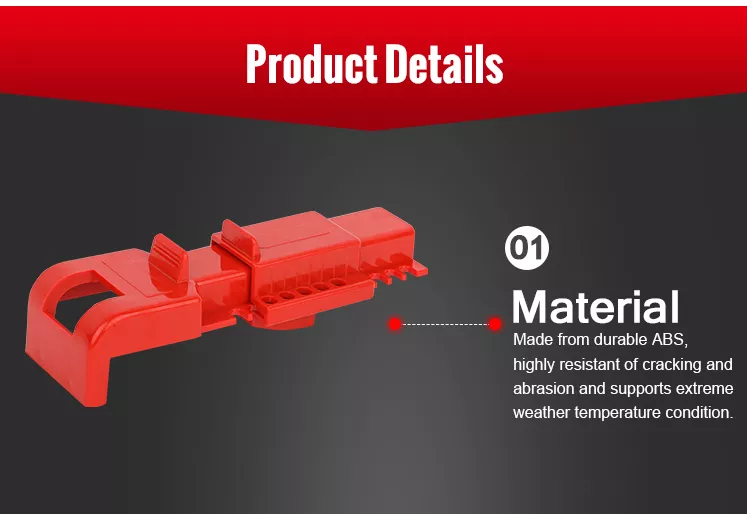

3. Durable Construction: To withstand the rigors of industrial environments, butterfly valve lockout devices are constructed using high-quality materials such as durable plastics or metals. This ensures longevity and reliability, even in harsh conditions.

4. Clear Visibility: Butterfly valve lockout devices are often designed in bright, highly visible colors, making them easily identifiable. Clear labels or tags can be attached to these devices, providing crucial information about the lockout status and authorized personnel.

Implementing Butterfly Valve Lockout Procedures:

To ensure the effective implementation of butterfly valve lockout procedures, organizations should follow these essential steps:

1. Develop a Lockout/Tagout Program: Establish a comprehensive lockout/tagout program that outlines the procedures, responsibilities, and training requirements for employees involved in valve maintenance or repair.

2. Identify and Assess Risks: Conduct a thorough risk assessment to identify potential hazards associated with butterfly valve operations. This assessment should consider factors such as energy sources, equipment specifications, and maintenance requirements.

3. Select Appropriate Lockout Devices: Choose butterfly valve lockout devices that are compatible with the specific valve types and sizes used in your facility. Ensure that these devices meet industry safety standards and regulations.

4. Train Employees: Provide comprehensive training to employees on the proper use of butterfly valve lockout devices and the associated lockout/tagout procedures. This training should emphasize the importance of safety and the potential consequences of improper lockout practices.

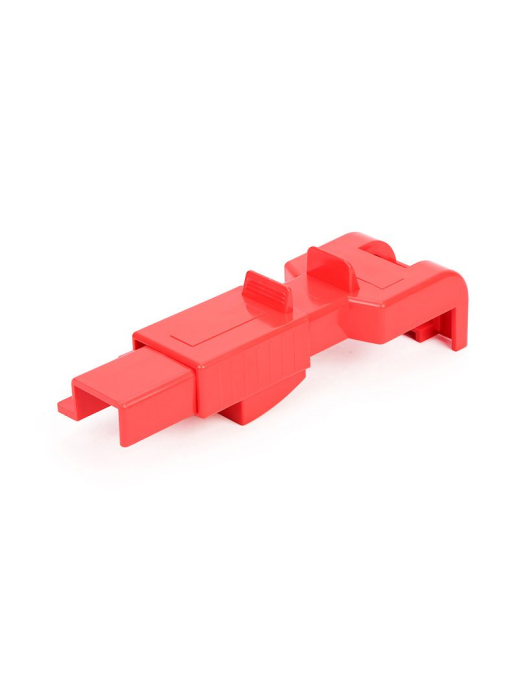

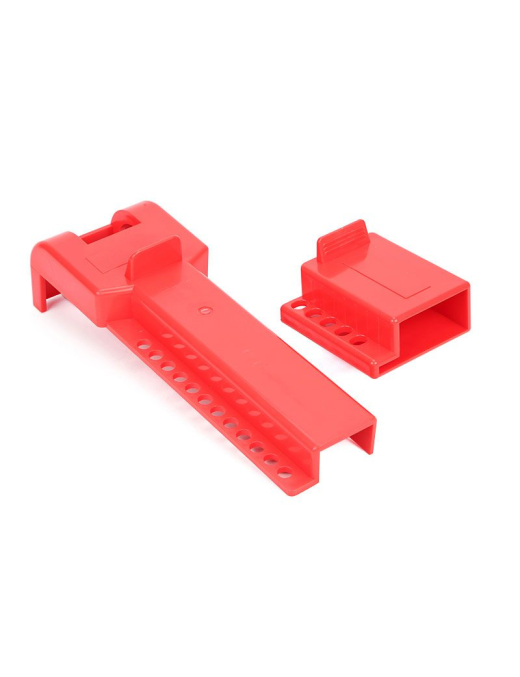

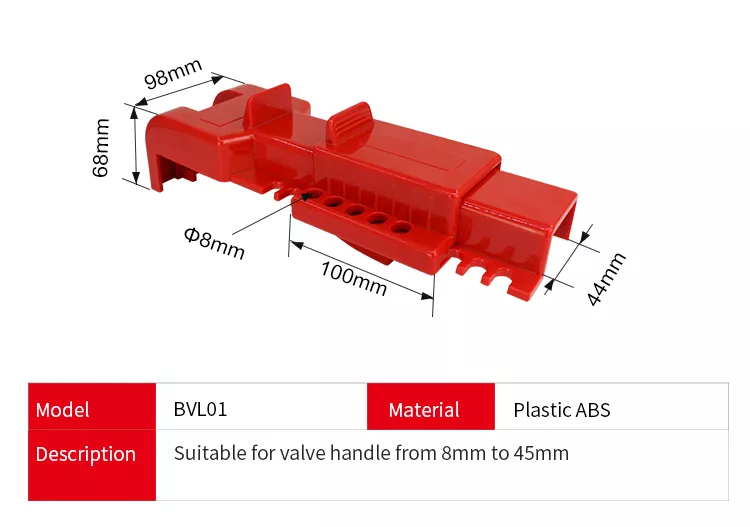

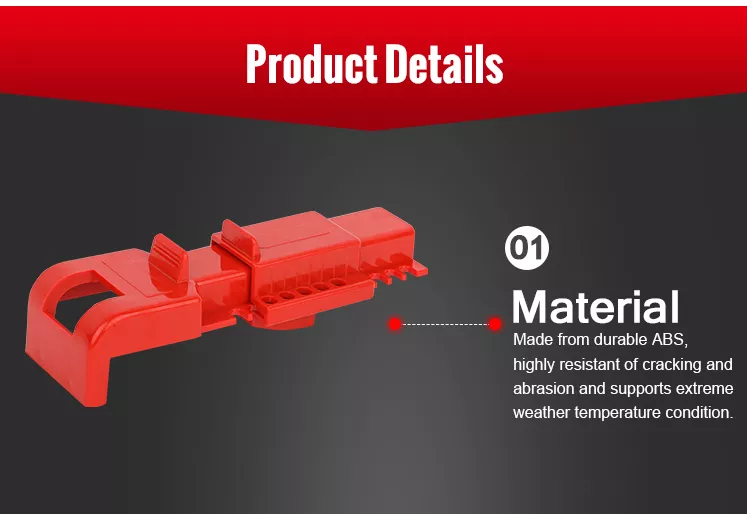

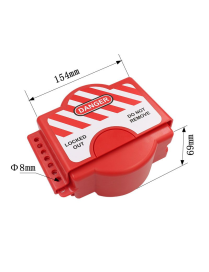

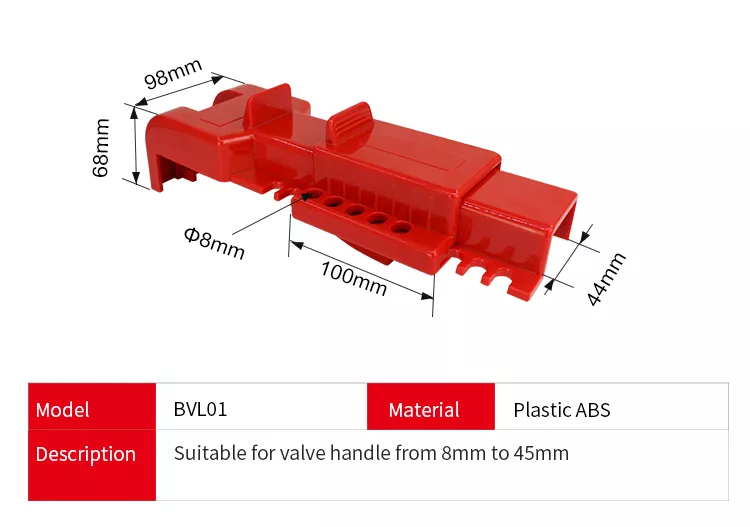

PRODUCT DETAILS:

Material: ABS750

Description: Butterfly Valve Lockout

Brand Name: Prolockey

Service Temperature Range °F: -20℃-90℃

Lock Holes: 8mm

Color: Red

Total Length: 303mm

Body Width: 98mm

Body Height: 68mm

Product Net Weight: 0.348kg

APPLICATION:

INSTALLATION STEPS:

Conclusion:

In the realm of industrial safety, butterfly valve lockout plays a crucial role in preventing accidents, protecting personnel, and ensuring efficient operations. By implementing robust lockout procedures and utilizing reliable lockout devices, organizations can effectively mitigate risks associated with butterfly valve operations. Prioritizing safety through the use of butterfly valve lockout systems not only safeguards employees but also enhances overall productivity and compliance with regulatory standards.

Security policy

Security policy

Delivery policy

Delivery policy

Return policy

Return policy