PRODUCT OVERVIEW

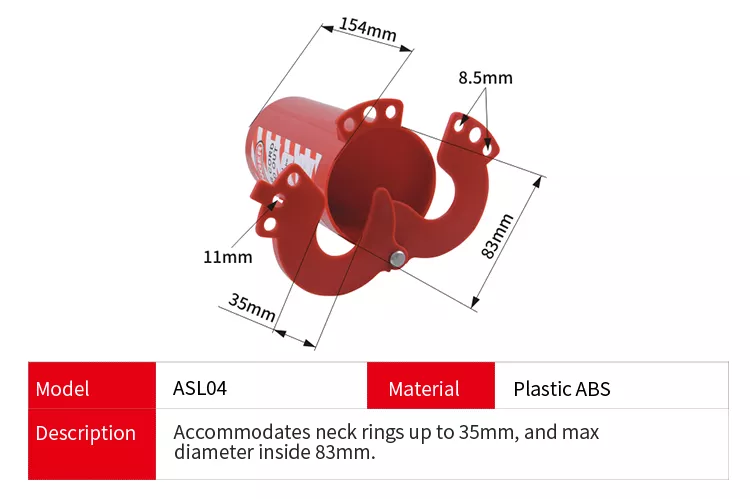

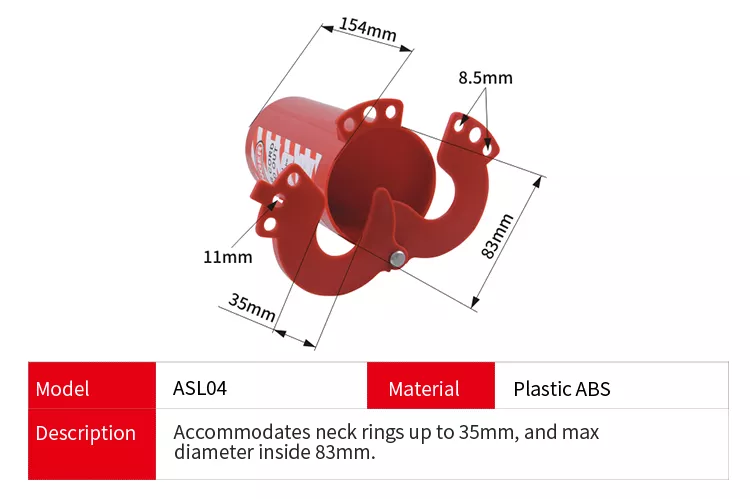

a) Made from engineering plastic ABS.

b) Prevents access to the main cylinder valve.

c) Accommodates neck rings up to 35mm, and max diameter inside 83mm.

d) Easy and efficient installation to save you time.

e) Can be locked with 3 padlocks, lock shackle diameter up to 8.5mm.

PRODUCT FEATURES

Product Number: ASL04

Material: ABS750

Description: Air Source Lockout

Brand Name: Prolockey

Service Temperature Range °F: - 20℃-90℃

Lock Holes: 8.5mm

Color: Red

Inner Diameter: 94mm

Total Length: 167mm

Hole Diameter: 36mm

Product Net Weight: 0.154kg

Steps to Implement Gas Cylinder Pneumatic Lockout Device/Air Source Lockout :

1. Identify the air source: Before starting any maintenance or repair work, it is important to locate and identify the air source that powers the equipment. This could be a compressor, air tank, or any other source of compressed air.

2. Notify all affected personnel: Inform all employees working in the area about the planned maintenance or repair work and the need for air source lockout. Make sure everyone is aware of the potential hazards and the importance of following proper lockout procedures.

3. Shut off the air source: Turn off the air supply to the equipment by closing the main valve or switch. This will prevent any air from flowing into the system and ensure that the equipment remains in a safe, non-operational state.

4. Release residual pressure: Even after shutting off the air source, there may still be residual pressure in the system. Release this pressure by activating the equipment's controls or using bleed valves to ensure that the system is depressurized.

5. Lock out the air source: Once the air source is shut off and the pressure is released, lock out the air source using a lockout device such as a lockout tag or padlock. This will prevent anyone from inadvertently turning on the air supply while maintenance work is being performed.

Benefits of Air Source Lockout:

Implementing air source lockout procedures in the workplace offers several benefits, including:

- Enhanced safety for workers performing maintenance or repair work

- Compliance with OSHA regulations and industry standards

- Prevention of accidents and injuries caused by accidental start-up of equipment

- Protection of equipment from damage during maintenance work

- Peace of mind knowing that proper safety measures are in place to prevent hazardous energy sources

Conclusion:

Air source lockout is a critical safety measure that must be implemented in workplaces where compressed air is used to power equipment. By following the steps outlined in this article and ensuring that proper lockout procedures are in place, employers can protect their workers from potential hazards and create a safer work environment. Remember, safety should always be the top priority in any workplace, and air source lockout is an important step in achieving that goal.

Security policy

Security policy

Delivery policy

Delivery policy

Return policy

Return policy