The Importance of Blind Flange Valve Lockouts:

1. Preventing Accidental Activation: Blind flange valve lockouts act as a visual deterrent, reminding workers that the valve is under maintenance or repair. This prevents accidental activation, which could lead to hazardous situations or damage to equipment.

2. Compliance with Safety Regulations: Many industrial environments are subject to strict safety regulations. Blind flange valve lockouts help organizations comply with these regulations by ensuring that valves are properly secured during maintenance or repair work.

3. Enhancing Worker Safety: By effectively locking out valves, blind flange valve lockouts protect workers from potential harm. Accidental activation of valves can release hazardous substances, cause sudden pressure surges, or result in unexpected equipment movements. By preventing such incidents, blind flange valve lockouts contribute to a safer working environment.

4. Time and Cost Savings: Implementing blind flange valve lockouts during maintenance or repair work can save organizations both time and money. By preventing accidental valve activation, potential damage to equipment is avoided, reducing the need for costly repairs or replacements. Additionally, the use of blind flange valve lockouts minimizes downtime by ensuring that maintenance work can be carried out efficiently and safely.

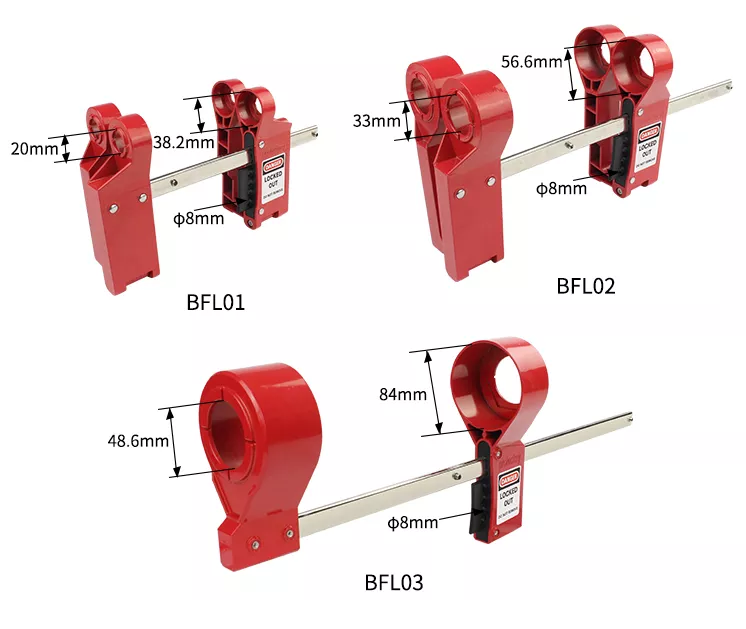

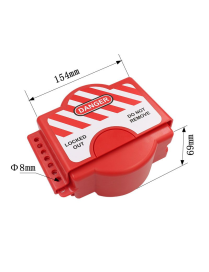

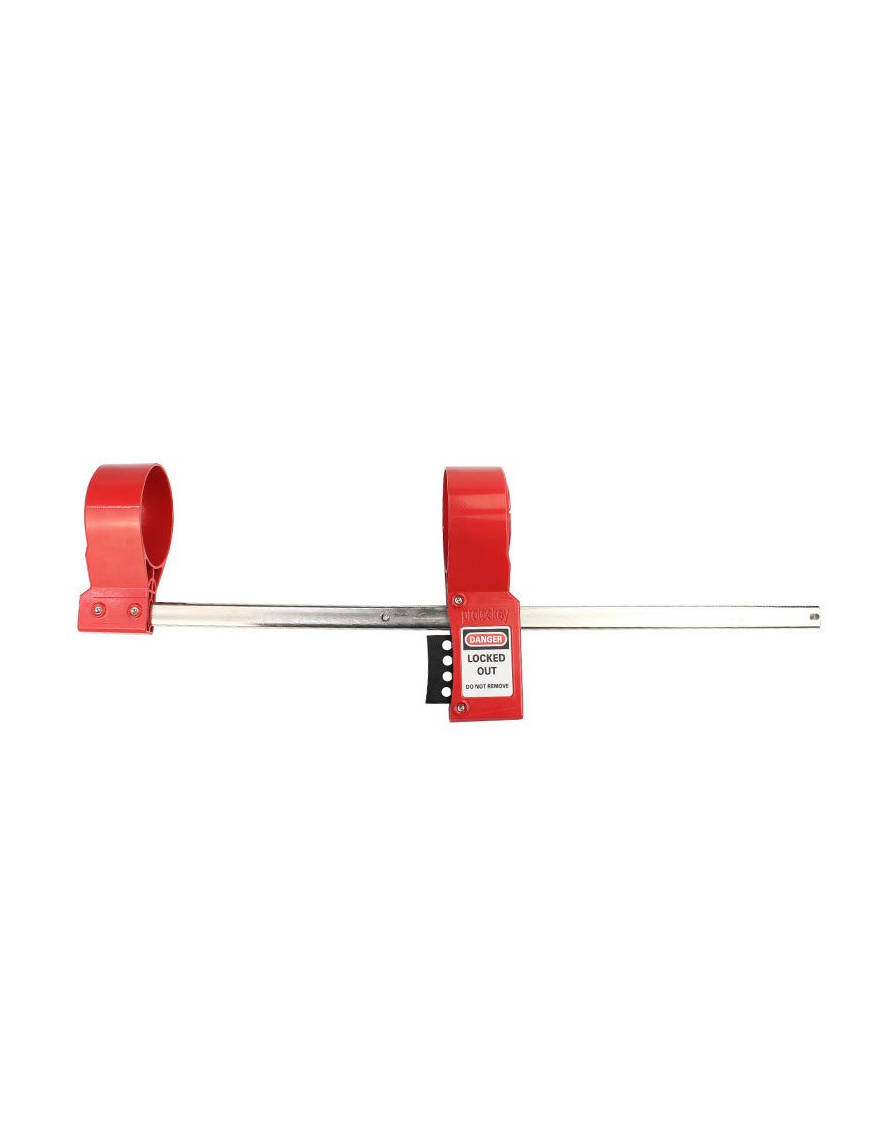

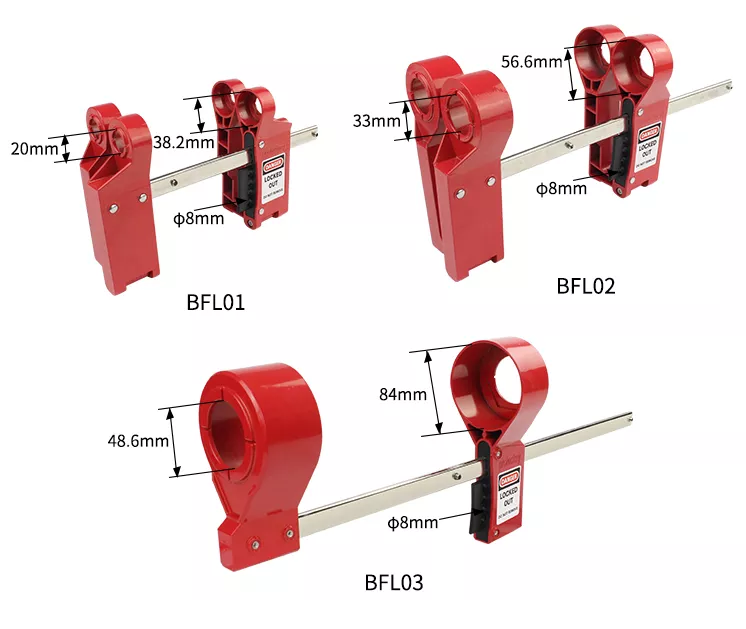

PRODUCT DETAILS:

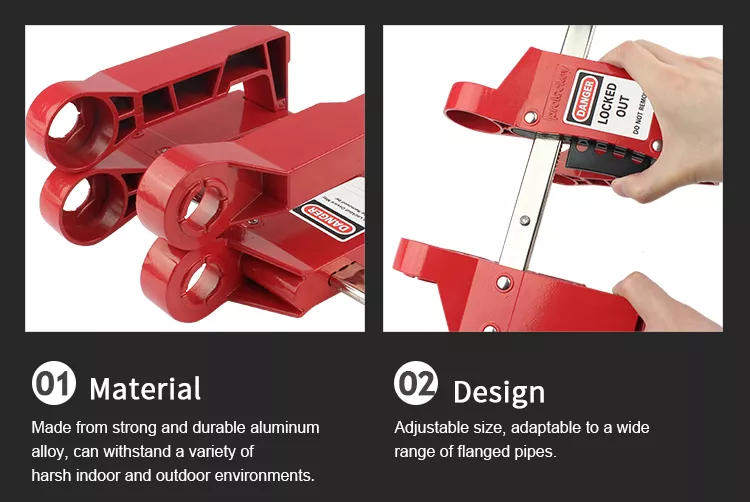

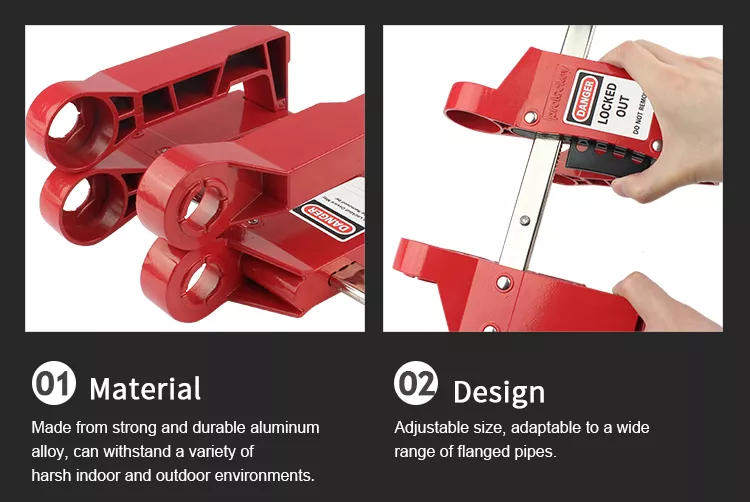

a) Made from strong and durable aluminum alloy, can withstand a variety of harsh indoor and outdoor environments

b) Hidden flange nut when locked, prevent misuse.

c) Adjustable size, adaptable to a wide range of flanged pipes.

d) Accepts up to 4 management holes for locking.

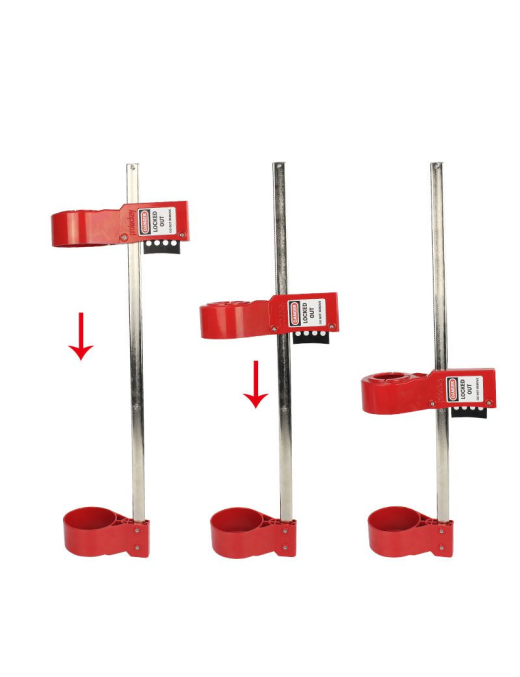

INSTALLATION STEPS:

Choosing the Right Blind Flange Valve Lockout:

When selecting blind flange valve lockouts, it is essential to consider certain factors. These include the size and type of valve, the material and durability of the lockout device, and compatibility with existing safety protocols. Consulting with safety experts or suppliers can help organizations make informed decisions and choose the most suitable blind flange valve lockout for their specific needs.

Conclusion:

Blind flange valve lockouts play a vital role in ensuring safety in industrial environments. By preventing accidental activation of valves during maintenance or repair work, these devices protect workers from potential harm and help organizations comply with safety regulations. Investing in high-quality blind flange valve lockouts not only enhances worker safety but also saves time and costs associated with equipment damage. Prioritizing safety through the use of blind flange valve lockouts is a proactive step towards creating a secure and productive working environment.

Security policy

Security policy

Delivery policy

Delivery policy

Return policy

Return policy