PRODUCT OVERVIEW

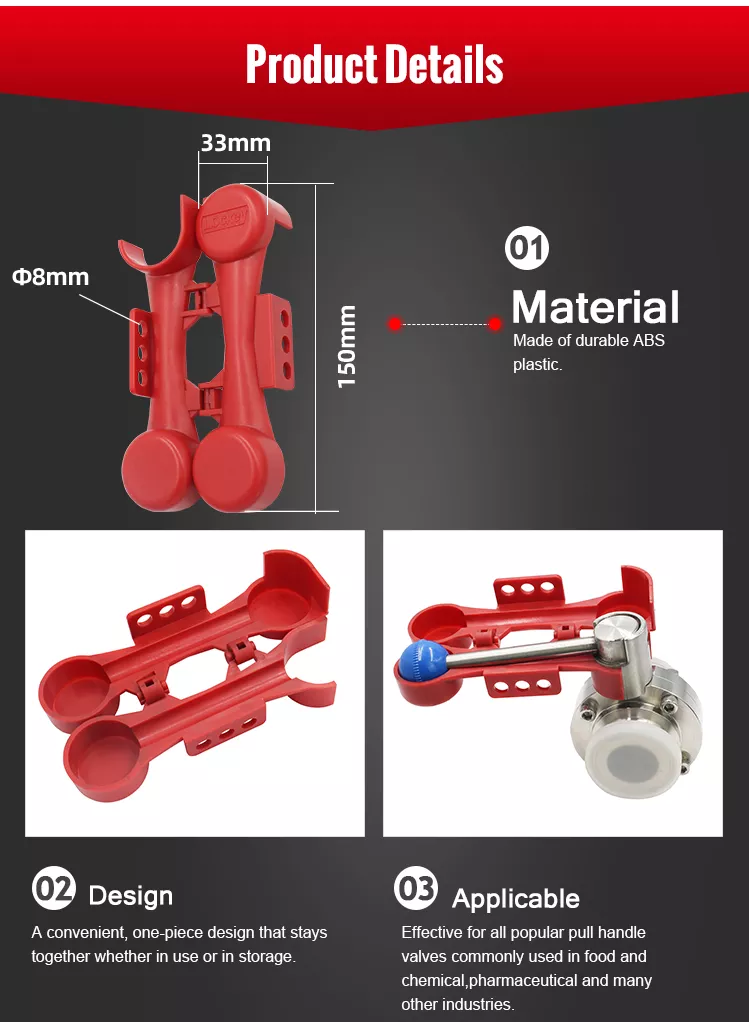

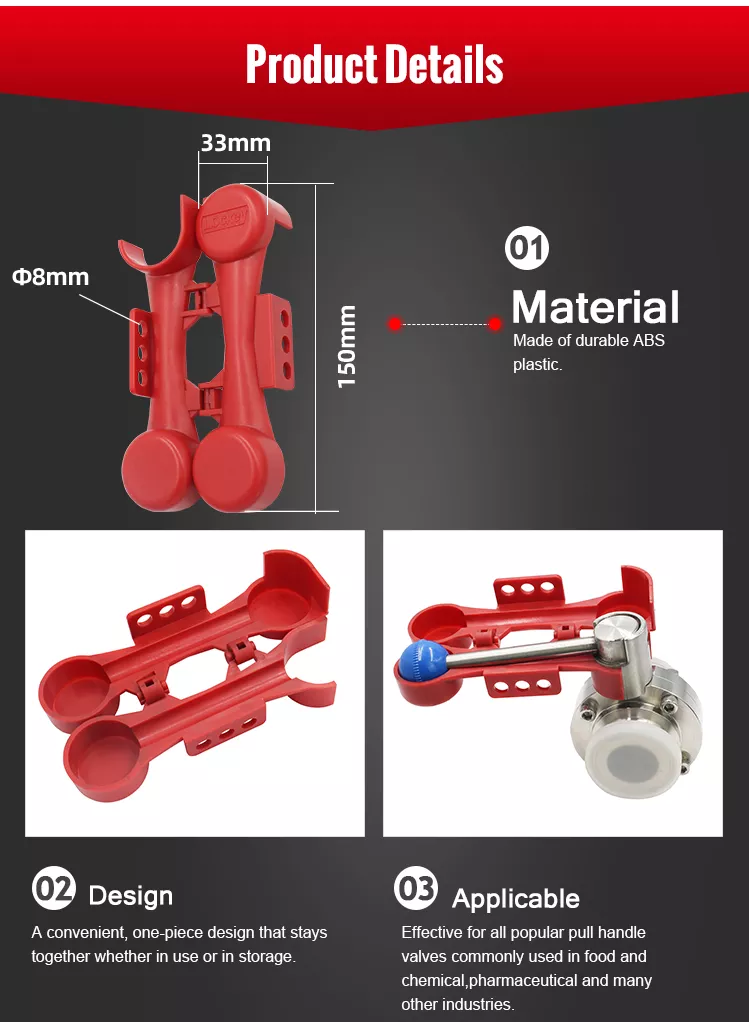

a) Made of durable ABS plastic.

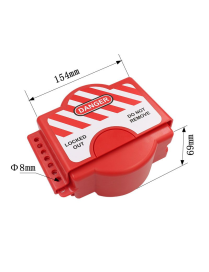

b) Exclusive, anti-pivot lockout device fits the full range of pull handle valve sizes, from ½ in. to 8 in. diameter.

c) A convenient, one-piece design that stays together whether in use or in storage.

d) Holds up to three worker padlocks.

e) Effective for all popular pull handle valves commonly used in food and beverage, water utilities, chemical, pharmaceutical and many other industries.

f) Secures the valve handle in any desired position, from fully closed, to partially or fully open.

Product Number: BVL31

Material: ABS750

Description: Butterfly Valve Lockout

Brand Name: Prolockey

Service Temperature Range °F: -20℃-90℃

Lock Holes: 8mm

Color: Red

Total Length: 150mm

Body Width: 98mm

Body Height: 68mm

Rod Length: 79mm

Product Net Weight: 0.045kg

When it comes to butterfly valves, lockout tagout procedures are crucial for several reasons:

1. Preventing Accidental Operation: By implementing lockout tagout procedures, workers are protected from the accidental operation of butterfly valves while maintenance or repair work is being carried out. This eliminates the risk of sudden valve movement, which can lead to severe injuries or even fatalities.

2. Compliance with Regulations: In many countries, lockout tagout procedures are mandated by law to ensure workplace safety. Failure to comply with these regulations can result in hefty fines and legal consequences. By implementing proper lockout tagout procedures for butterfly valves, industrial facilities can demonstrate their commitment to safety and avoid legal issues.

3. Enhancing Communication: Lockout tagout procedures involve the use of standardized tags that provide essential information about the ongoing maintenance or repair work. These tags indicate who is performing the work, when it started, and when it is expected to be completed. This clear communication helps prevent misunderstandings and ensures that everyone involved is aware of the ongoing activities.

Implementing Butterfly Valve Lockout Tagout:

To effectively implement butterfly valve lockout tagout procedures, industrial facilities should follow these steps:

1. Develop a Comprehensive Lockout Tagout Program: Establish a written lockout tagout program that outlines the specific procedures and responsibilities for locking out and tagging out butterfly valves. This program should be communicated to all employees and regularly reviewed to ensure its effectiveness.

2. Identify Energy Sources: Conduct a thorough assessment to identify all energy sources associated with butterfly valves. This includes electrical, mechanical, and pneumatic energy sources. Document these sources and ensure that they are clearly labeled for easy identification.

3. Provide Training: Train all employees on the proper lockout tagout procedures specific to butterfly valves. This training should cover the importance of lockout tagout, how to properly lock out and tag out butterfly valves, and the potential risks associated with improper procedures.

4. Use Reliable Lockout Devices: Invest in high-quality lockout devices that are specifically designed for butterfly valves. These devices should effectively immobilize the valve disc, preventing any accidental operation. Additionally, ensure that the lockout devices are compatible with the facility's existing lockout tagout system.

5. Regularly Inspect and Review: Conduct regular inspections to ensure that lockout tagout procedures are being followed correctly. Review the effectiveness of the program and make any necessary improvements based on feedback from employees and observations made during inspections.

INSTALLATION STEPS

Conclusion:

Butterfly valve lockout tagout procedures are essential for maintaining a safe working environment in industrial settings. By preventing accidental operation, ensuring compliance with regulations, and enhancing communication, these procedures contribute to the overall safety and well-being of workers. Implementing a comprehensive lockout tagout program specific to butterfly valves, providing adequate training, and using reliable lockout devices are key steps in ensuring the success of these procedures. By prioritizing safety and compliance, industrial facilities can create a secure environment where workers can perform their tasks with confidence and peace of mind.

Security policy

Security policy

Delivery policy

Delivery policy

Return policy

Return policy